Garments Testing Machine

Universal Wear Tester, to determine the wear and abrasion resistance of fabric used in clothing, footwear and industrials. Hydrostatic Head Tester, used for determining the resistance of fabrics (canvas, coated fabrics, cover cloth, rainproof clothing fabrics and geotextile materials) and films to water penetration under pressure while firmly clamped in the test rig of standard area, by means of dynamic test method and static test method.

Color Matching Cabinet, used for color matching or assessment of all industries and applications where there is a need to maintain color consistency and quality.

They comply with ASTM D3514/D3885/D3886, AATCC 119/120, FTMS 191/5300/5302, AATCC 127, ISO 811/1420A, EN 20811, ASTM D1729, BS 950 PART1, BS 950 PART1, etc.

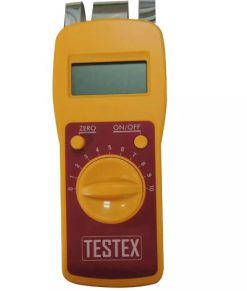

Moisture Management Tester TF128

Moisture Management Tester is a handy device to determine the dynamic liquid transportation properties of fabrics, such as knitted, woven textiles, and non-woven textile fabric in 3 dimensions. Moisture Management tester can test the resulting base on water resistance, including the fabric’s geometric and internal structure.

Absorption Rate – Moisture absorbing time of the fabric’s inner and outer surfaces.

One-way Transportation Capability – Liquid moisture one-way transfer from the fabric’s inner surface to the outer surface.

Spreading / Drying Rate – Speed of liquid moisture spreading on fabric’s inner and outer surfaces.

Note: A customized PC is needed for this instrument.

The features of the Moisture Management Tester TF128

Fast and accurate testing: simply place the sample between the upper and lower sensors of the instrument, then drop the solution on the sample, when the solution passes through the sample,

it will generate the corresponding moisture content value, and the HD camera records the movement of moisture synchronously and forms the curve image on the computer side synchronously.

Easy to use: simple buttons, open case, and center light on the sensor make it easier for the tester to operate the instrument, and to place the sample precisely.

Protective set-up: the transparent shield protects the sample, ensuring the stability of the test process and the accuracy of the results.

Very comprehensive test results: can determine the performance of liquid moisture management in multiple directions, the test solution is generally transferred to the material fabric in three directions:

diffusion outward on the upper surface of the fabric; transfer from the upper surface to the lower surface through the fabric; diffusion outward on the lower surface of the fabric.

The moisture management tester permits the measurement of the following indexes

- Wetting Time Top / Bottom (WTT / WTB)

- Absorption Rate Top / Bottom (TAR / BAR)

- Maximum Wetted Radius Top / Bottom (MWRT / MWRB)

- Spreading Speed Top / Bottom (TSS / BSS)

- Accumulative One-Way Transport Capacity (R)

- Overall Moisture Management Capacity (OMMC)

Specifications

| Analysis Software | Offered |

| Interface | USB 1.1/2.0 |

| Power Supply | 110V~230V 50Hz/60Hz 1 A |

| Operation Temp & R. H. | 18°C to 40°C, 20% to 80% (non-condensing) |

| Pump On Time | 20 sec |

| Test Solution | Conductivity – 16 mS± 0.2 mS |

| Weight | 15 Kg |

| Dimensions | 360 x 200 x 250mm (L x W x H) |

Standards

| AATCC 195 | GB/T 21655.2 |

Why choose TESTEX Moisture Management Tester TF128

Strictly meet standards

All data for TF128 meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples, the same machine, and after multiple tests, the results are consistent.

High reproducibility

With the same set of samples, and different machines of the same model, and after multiple tests, the results are consistent.

Longer service life

For all the Moisture Management Testers manufactured by TESTEX, before mass production, prototypes are made and required to pass the strict Reliability Test, i.e. tested under challenging environments such as high and low temperature, high speed and high load, etc., to ensure the expected serving life no less than 8 years.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time).

And all spare parts, 3 months free warranty. Beyond the warranty period, services and accessories are charged at actual cost only.

We provide full life-cycle support for Moisture Management Tester TF128, so feel free to contact our service team with any questions you may have.

Đánh giá

Chưa có đánh giá nào.