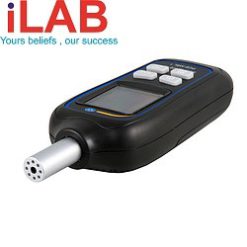

Surface roughness tester PCE-CT 26FN

For ferric and non-ferric substrates / Large measuring range / Rotatable color display / Light weight

The PCE-CT 26FN Surface Conditioner non-destructively measures coating thickness (lacquers, paints, laminates, etc.) on ferric and non-ferric metals. The surface condition monitor is ideal for detecting, for example, if a vehicle has had an accident. On the other hand, this surface condition controller is also used in industry for quality control, thus guaranteeing that the quality of the product is identical.

The surface roughness controller has an ergonomic design and integrates the measurement probe. Its use is simple and allows you to measure quickly and accurately. The PCE-CT 26N surface condition tester has been designed to measure the thickness of non-magnetic coatings (such as lacquers, plastic coatings, chrome, copper, zinc, anodized, etc.) on bases ferric, such as iron and steel. It also measures the thickness of insulating coatings, such as lacquers, anodized, paper, glass, rubber, etc. on non-ferric bases, such as copper, aluminum, brass, stainless steel.

Application / Use

Simply lay the surface texture tester on the material to be measured and read the value on the display. In this simple way you can measure the thickness or coating of lacquers, paints, plastic coatings, chrome, copper, zinc, galvanized, enamel on steel, stainless steel , ferric and non-ferric metals, as well as anodized on aluminum.

The calibration standards included in the contents of the shipment allow the surface roughness monitor to be adjusted at any time. To do this, place a calibration standard on a plate (Fe or NFe) and place the surface condition controller on the calibration standard. Make sure the device is upright and positioned correctly.

– Wear-resistant sensor

– V-slot for measuring in pipes

– One-handed

operation – ISO calibration optional

– Carrying case included

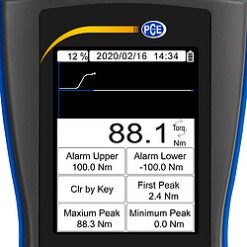

| Measuring range | 0…1250 µm (0…50 mil) |

| Resolution | 1 µm (0.1 mil) |

| Precision | ± (3% + 2 µm) or ± (3 % + 0.1 mils) |

| Minimum measurement area | 5x5mm |

| Minimum bend radius | Convex: 3mm / Concave: 50mm |

| Minimum substrate thickness | Fe: 0.5mm NFe: 0.3mm |

| Screen | OLED |

| Ambient conditions | 0 … +50°C (+32 … +120°F) |

| Feed | 2 x 1.5 V batteries, type AAA |

| Dimensions | 100 x 52 x 29mm |

| Weight | Approx. 68 g (without batteries) |

1 x PCE-CT 26FN surface roughness tester

2 x 1.5 V batteries, type AAA

1 x Set of calibration standards (5 units)

1 x Ferric (Fe)

base plate 1 x Non- ferric base plate ferric (NFe)

1 x Carrying case

1 x User manual

Đánh giá

Chưa có đánh giá nào.